HAWAMID applications

Directly to the info

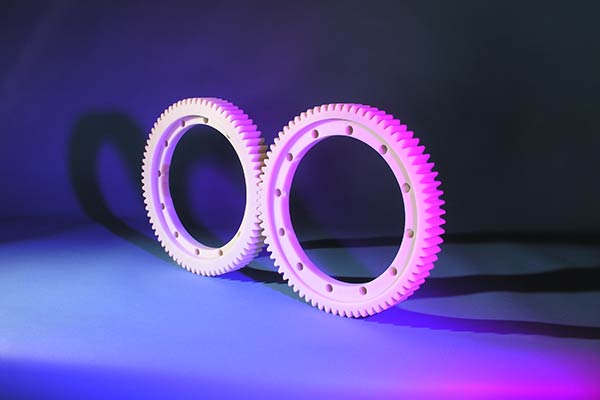

Gear wheels

The superiority of plastic gears

Even if gear wheels made of plastic do not come near to the load capacity values of metallic materials, plastics are superior to metals in other ranges of requirements. Plastic gear wheels are characterised by:

- Low weight and thus low mass inertia and low energy requirement

- Vibration damping

- Noise reduction

- Corrosion resistance

HAWAMID PA 12G is furthermore characterised by:

- Especially high abrasion resistance

- Especially good self-lubrication and dry-run properties

- Dimensional stability and unvarying mechanical strength even in damp/wet environments thanks to low water absorption

- Especially high load capacity in the case of intermittent load peaks

- High accuracy in fitting in the case of pressed-in ball bearings thanks to low creep behaviour

- Largely stable mechanical values across wide range of temperatures between -50°C and +120°C during continuous operation

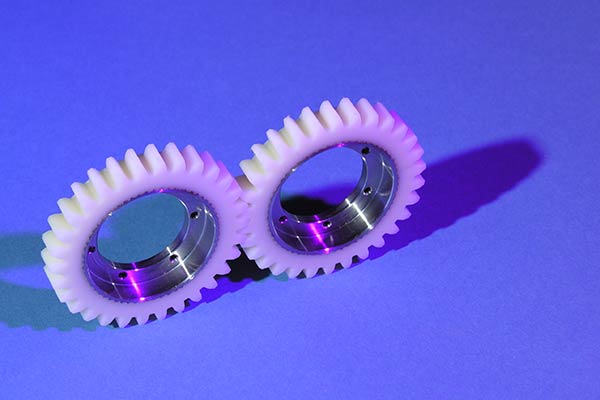

HAWAMID PA 12G + FE offers additional advantages thanks to hybrid connection

- Transfer of high forces via metal hub to plastic lining

- Fast removal of heat

- Design according to steel standards

HAWAMID PA 12G + oil enhances the antifriction and dry-run properties yet again thanks to the oil incorporated into the material.

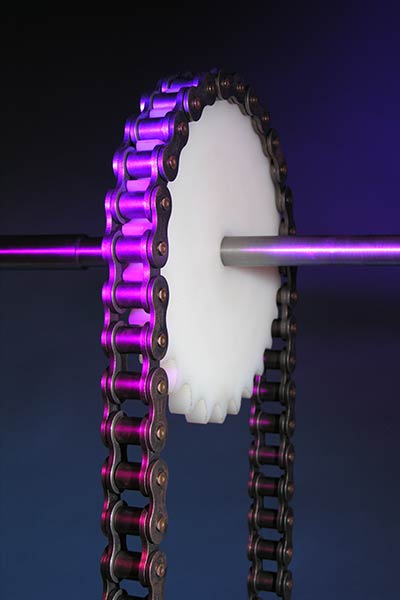

Sprockets

Low weight and lower moments of inertia

In the case of sprockets, similar material parameters are important as with gears. The low weight offers particular advantages when designing sprockets made of HAWAMID PA 12G. Considerably lower moments of inertia can be expected during acceleration and braking. Combined with the sliding friction and dry-run properties PA 12G is an ideal material for maintenance-free constructions.

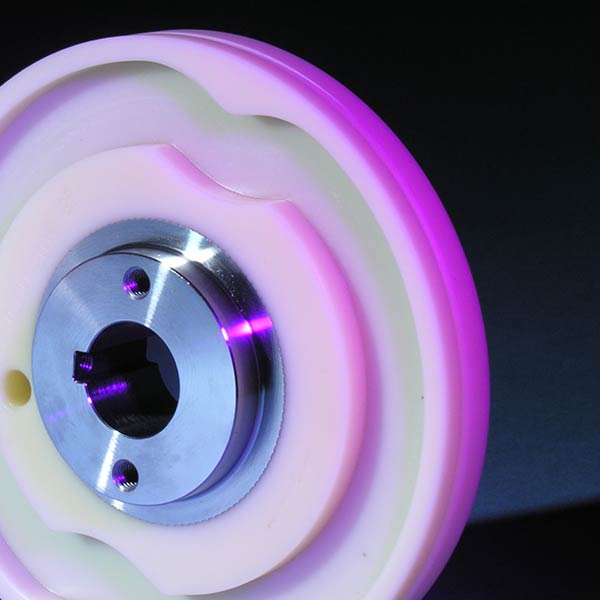

Runners

Outstanding mechanical properties of track rollers

HAWAMID PA 12G exhibits a number of mechanical properties required in particular in applications using runners and which are not or only insufficiently offered by metals and other plastics such as POM or PET:

- The high restoring force in conjunction with the high load limits prevent the rollers from flattening out. After being deformed by static loads the material quickly returns to its original shape, thus ensuring vibration-free concentric running, low rolling resistance and little wear.

- Thanks to the low creep behaviour of PA 12G across a wide range of temperatures the pressed-in ball bearings do not become loose even when subjected to static loads – a decisive criterion for high-precision guide materials.

- HAWAMID PA 12G is noise-absorbing, vibration-absorbing and especially resistant to intermittent peak loads.

- The hybrid connection HAWAMID 12G + FE with metal hubs allows for high power transmission onto the runner during acceleration and braking.

- The toughness and abrasion resistance allow for long operating times. Ideal partners have been found by pairing a HAWAMID PA 12G runner with a metal runner track. Little wear, smooth running properties and reduced strain on the running track are thus possible even in the case of high loads.

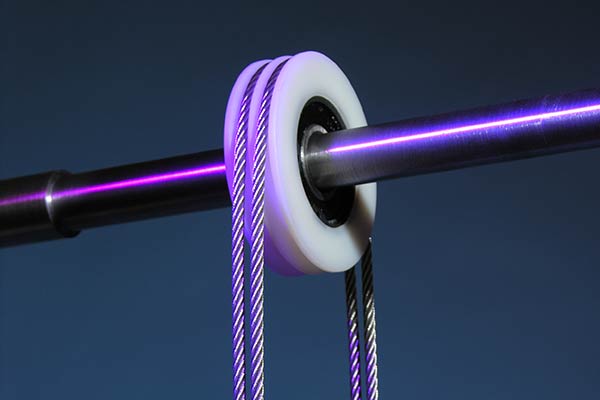

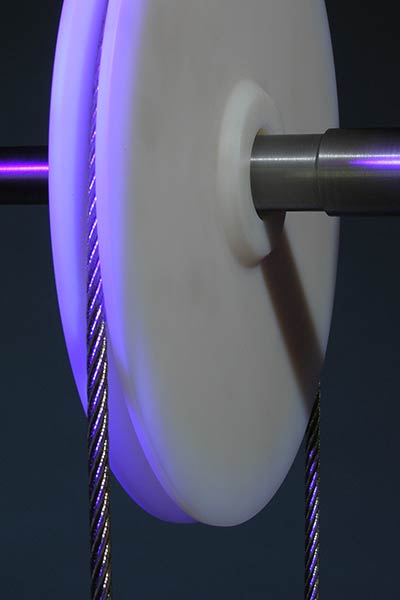

Pulleys

Pulleys with high load limits

The arguments in favour of HAWAMID PA 12G being used for pulleys are its high abrasion resistance and elasticity. Here too the pairing of the material PA 12G with a steel cable results in long operating times and smooth running properties. Under load the elastic PA 12G gives way – the cable presses into the pulley – thus increases the bearing surfaces of the individual cable strands and reduces the surface pressure: the cable has a much longer service life compared to when used with metal pulleys.

Compared to PA 6G, HAWAMID PA 12G not only has higher load limits but can also be used in damp, wet or cold environments without becoming soft, bursting during frost, becoming brittle or losing its mechanical strength.

Friction bearings, sliding plates

HAWAMID PA 12G + oil for sliding applications

HAWAMID PA 12G and especially HAWAMID PA 12G + oil are ideal materials for high-load sliding applications since they meet all essential requirements:

- Good antifriction and emergency running properties

- High abrasion resistance

- Good damping capacity especially in the case of intermittent loads

- High dimensional stability even in wet environments

- Chemical-resistant

- Corrosion-resistant

- Approved for food handling

- Wide range of temperatures during continuous operation

Here too the advantages over PA 6G lie in the higher degree of crystallinity which makes HAWAMID PA 12G more resilient and ensures minimal water absorption.

When choosing materials for sliding applications, not only the mechanical values are important but also the resistance of the sliding partners against ambient conditions and the media used.

Wherever the use of lubricants is possible, running-in lubrication is recommended in order to increase operating times.

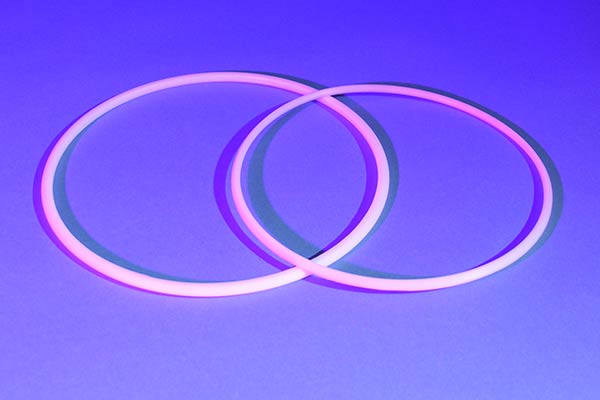

Gaskets

Highly resilient gaskets

Depending on the ambient conditions and media used, HAWAMID PA 12G is also a suitable material for producing heavy-duty gaskets.

The properties are combined in one material – an unusual composition:

- chemical-resistant

- high elasticity and resilience

- no flattening out when subjected to continuous static loads

- highly resistant against abrasive media

- wide range of temperatures in the case of peak loads and continuous loads and

- low water absorption / swelling behaviour

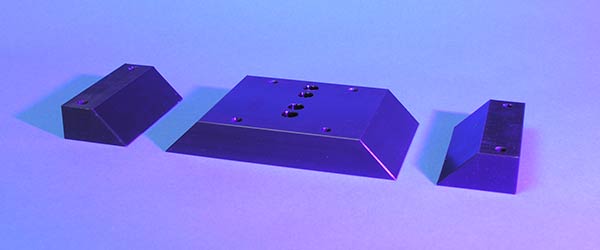

Cam discs

Polyamide 12 cast as ideal cam disc

Low inertia mass, good dry-run properties, wear resistance and exacting tolerances are the material requirements of cam discs. HAWAMID PA 12G meets these requirements even in damp environments and when exposed to long-term temperatures of -40°C to +120°C.

Spindle nuts

Spindle nuts

(linear guides, lift tables)

The thread requires good antifriction and wear resistance properties, and strength and elasticity are required for the load transfer. HAWAMID PA 12G + oil – self-lubricating – offers itself as the ideal material. In particular in applications where dust comes in contact with lubricants and causes a lot of wear on nuts and spindles. Because HAWAMID PA 12G + oil can be used in dry-running applications without the use of additional lubricants.

Pump impellers, pump back plate

HAWAMID PA 12G – better than high-alloy stainless steel

Pumps are particularly prone to high wear. HAWAMID PA 12G withstands pressure, vacuum, high speeds and abrasive media better than high-alloyed stainless steels. And it does so with a considerably lower weight.