Technical appendix at a glance

Diagrams of HAWAMID PA 12G

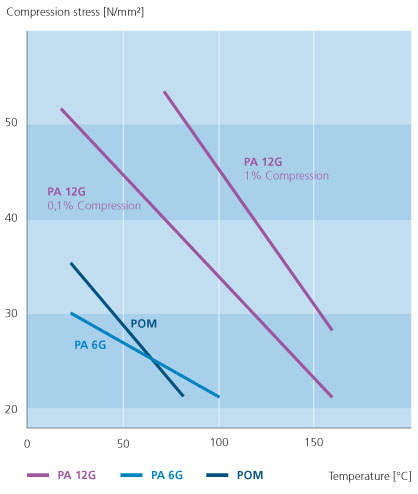

Compressive stress / temperature

Even at ambient temperatures as low as 23°C the permissible compression stress of PA 12G is 43% or rather 31% higher than with OPM or PA 6. If the temperature rises, the application limits are soon reached with POM and PA 6. PA 12G, however, exhibits good elastic recovery and low creep behaviour across a wide range of temperatures.

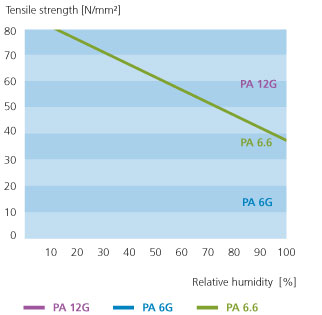

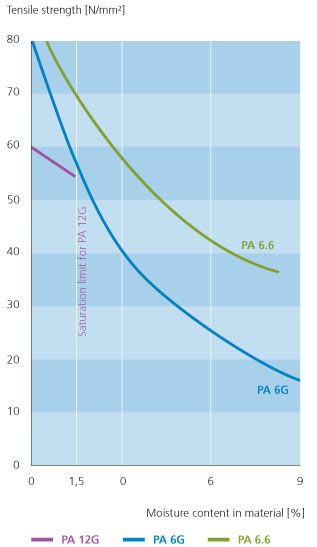

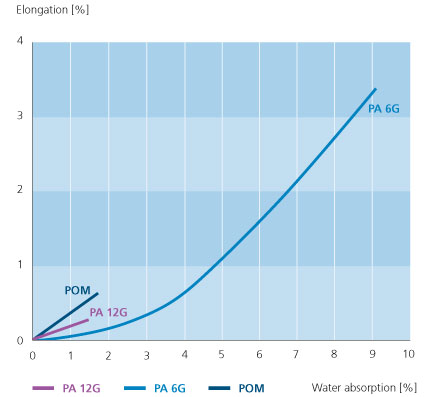

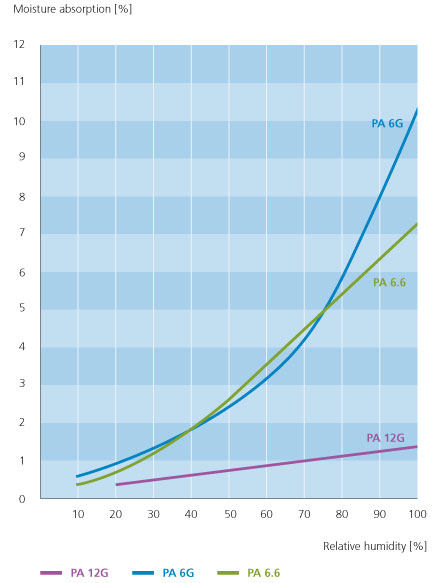

Moisture absorption / rel. humidity

Owing to its high moisture absorption, PA 6 exhibits lower strength and, due to its swelling behaviour, lower dimensional ssliderility. In the case of frost, there is also the risk of bursting. PA 12G is saturated at 1.1% – this means lasting dimensional ssliderility and strength even in damp environments and at temperatures as low as -50°C.